SUPPORTING BUSINESS' REPUTATION. IMPROVING USER EXPERIENCE

When users see an RCP product, whether it’s for waste and recycling, hand hygiene, washroom, cleaning, or material handling, they know it’s the mark of quality and trust. That’s why our products can be found across sites around the globe, from office buildings to shopping centres, and from warehouses to construction sites.

From 6 April 2024, businesses in Wales must separate their waste for recycling. Download our free guide to what’s changing, the cost benefits of better recycling, and what to look for when choosing recycling bins.

SOLUTIONS DESIGNED TO LAST

Warranties of up to 10 years on all refuse and recycling products, including our industry-renowned BRUTE® containers and Slim Jim® Vented ranges, help you implement effective recycling programs and reduce costs.

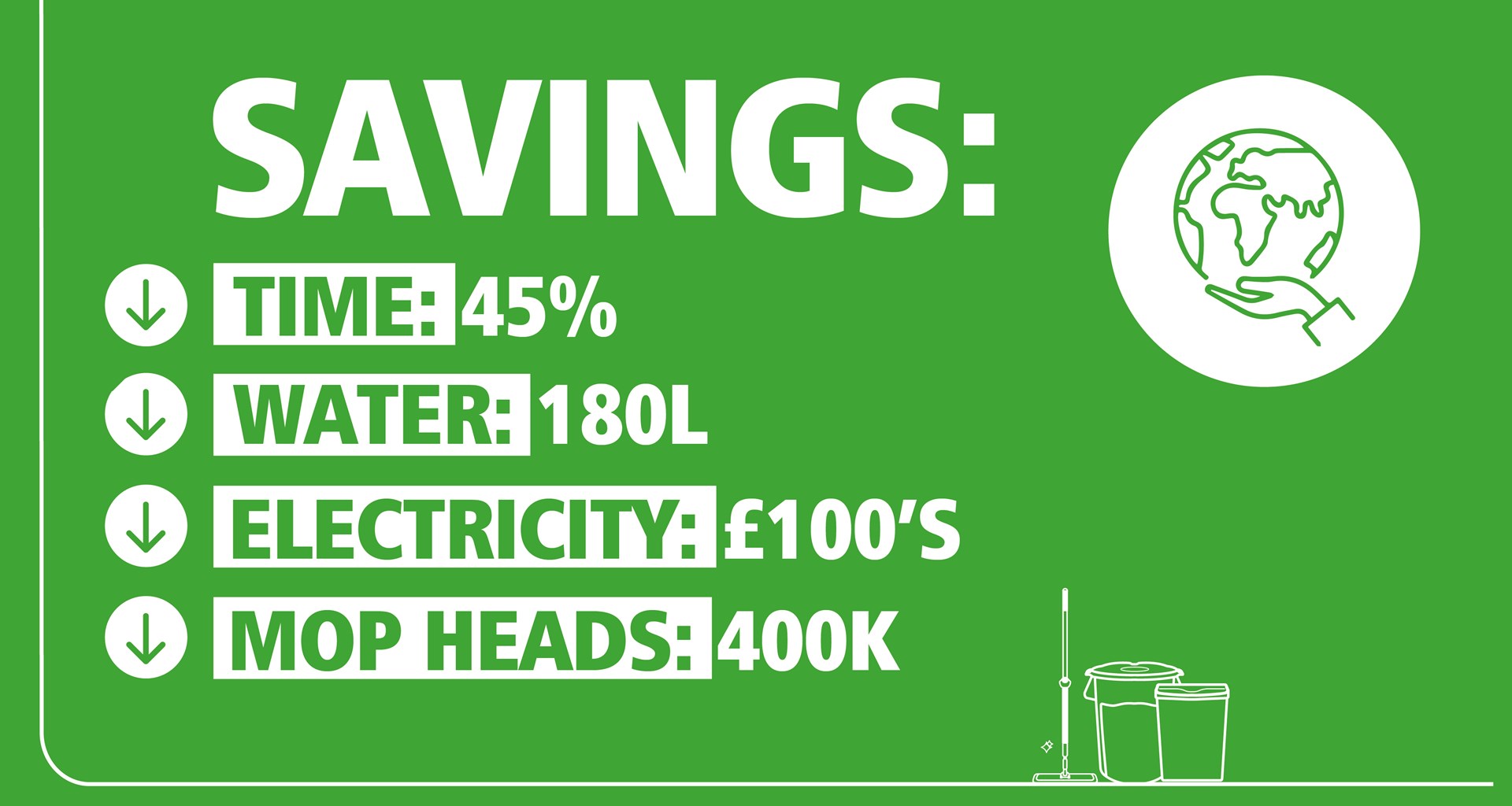

By championing product longevity and upgrading to ergonomically designed cleaning tools, Sanctuary Supported Living, has improved cleaning efficiency and effectiveness as well as improved their sustainability credentials. All without putting a strain on their commercial costs. Find out how your business could do the same.

From high environmental expectations to sickness and safety issues affecting your business’ performance, commercial challenges come at facility managers from every angle.

We’ll help you take control of these common issues:

Business costs are under scrutiny. By improving recycling rates, facilities can save more than just the environment. Answer six simple questions to see your business’ potential financial savings.

Take the 90-second audit

As the UN’s Sustainable Development Goal to reduce food waste prompts increased landfill tax, the cost of mixing food with waste could be substantial.

Separating food waste tips

Our myth busters and HandSafe Challenge guide the way to long-term cost savings, boosted productivity and better brand perception.

Take the challenge

With the introduction of Slim Jim Recycling Stations, DPD cut costs by 27% and is set to to divert 500 tonnes of waste a year.

Learn moreHOW TO WORK WITH US

Businesses work with us to improve the quality of their waste and recycling, hand hygiene, washroom, cleaning and material handling provision. Whatever the sector: from offices to warehouse and logistics, education settings, retail or hospitality, we have products designed to fit.

Take control of your cleaning and hygiene. Take the next steps with us: